Copper Busbar Current Carrying Capacity

Hence the total current carrying capacity of the copper 1200 Amps of 100mm width and 10 mm thickness. Section 20 Current-Carrying Capacity of Busbars discusses how to estimate the working current and temperature.

Complete Current Busbar Table Rectangular

Contactors are compact and can be field mounted easily.

. So the bus bar 100x25x15 is suitable for 1002515083000A incomer current. The busbar is permitted to be made of copper or aluminum. Drilling or enlarging holes in busbars can increase the current density and reduce current carrying capacity.

Bus bar Temperature details. Current carrying capacity The amount of electrical current a cable or piece of equipment can handle safely. Three poles two poles and single pole circuit breakers can be snapped ie.

The second option is to use a busbar as the common grounding electrode conductor. They are also used to connect high voltage equipment at electrical switchyards and low voltage equipment in battery banksThey are generally uninsulated and have sufficient stiffness to be. Operating Temperature of Bus bar θ85C.

Usually these devices feature multiple contacts. In 120V and 208V 1-Phase 3-Phase wiring systems the available voltage levels are as follows inside the main breaker panel. So as implied by the.

X 2 in and whatever length is needed for all the connections. For reference please see Ampacities of Copper Alloy C11000 Bus Bars or Aluminum to Copper Ampacity Comparison Chart. For both options grounding electrode conductor taps that are sized.

They are mainly used in the high current junction like breaker joint male female contact operation frequency converters etc. Finance Math Health Fitness and more calculators all brought to you for free. For example if we select busbar to be of the size 20mm x10mm with a length of 24m Wöhner item code -01624 and if we select air temperature of 35C and busbar temperature of 85C we will get the current carrying capacity 652A.

In case of aluminium bus bar the current carrying capacity is 08max. Electrical potential This is the amount of work that is required for an electric charge to move from one point to another. Designing for lower energy loss requires the use of more conductor material but results in more reliable operation due to the lower working temperature and because.

HL-2M is a medium-sized copper-conductor tokamak located at the Southwestern Institute of Physics SWIP in Chengdu China. The bus bar 100mm x25mm x15mm is suitable for incomer current 1002515124500A. In an electrical transmission network its required an electrical node but it is physically impossible to connect.

Aluminium and copper are the most available material in the earth but the copper conductor carries 40 extra current than the aluminium conductor. It is a totally new machine with some systems upgraded from the HL-2A tokamak that had been in operation since 2002. In electrical substations the bus bar is a common component where all the anchorages that have the same voltage level are connected.

The contacts are mostly normally open and they provide operating power to the load whenever the contactor. But the cost to sqmm points of view ie the cost of 3 core 35sqmm aluminium cable has Rs 16per sq. It turns out that ampacity is a combination of the words ampere and capacity.

Why Bus bar is required in an electrical transmission network. An ampere is a unit that describes the level of electrical current carried by the conductor material. By giving these inputs we can get the current carrying capacity of the Busbar.

Metal tracks hold the CB tightly over three busbars which draw hot from each busbar. Rated Voltage 415V50Hz Desire Maximum Current Rating of Bus bar 630Amp. In electric power distribution a busbar also bus bar is a metallic strip or bar typically housed inside switchgear panel boards and busway enclosures for local high current power distribution.

Aluminium and Copper Current Carrying Capacity Calculation Chart in Sqmm. HL-2M is designed to have 3MA plasma current and over 100 million degree Celsius ion temperature. Temperature rise of Bus.

Final Temperature of Bus bar during Faultθ1185C. Electrical current The movement of electrons through a conductor. In case of copper bus bar the current carrying capacity is 12max.

The bus bar is required to be sized a minimum of 6 mm 50 mm ¼ in. The contactor is mostly used in applications where higher current carrying capacity is involved while the relays are used for lower current applications. Copper busbar current carrying capacity 12 Busbar width Thickness in Amps.

What is an Ampacity Chart. Meter and copper conductor has Rs 30 per sqmm. Free and easy to use calculators for all of your daily problems.

Fault Current Isc 50KA Fault Duration t 1sec. Some equipment is constructed with fully rated busbars which have a typical current density of 1000 A per square inch of cross sectional area for copper and 750 A per square inch of cross sectional area for aluminum. However some equipment use busbars at a higher current.

In indoor substation copper or Aluminum bar is used as a bus bar. A higher working temperature means that energy is being wasted. Refer screen shot 3.

Calculate Size of Bus bar having Following Details Bus bar Current Details.

Busbar Size Calculation Formula Aluminium And Copper Examples Wira Electrical

What Is The Current Carrying Capacity Of Cu Bus Bars Quora

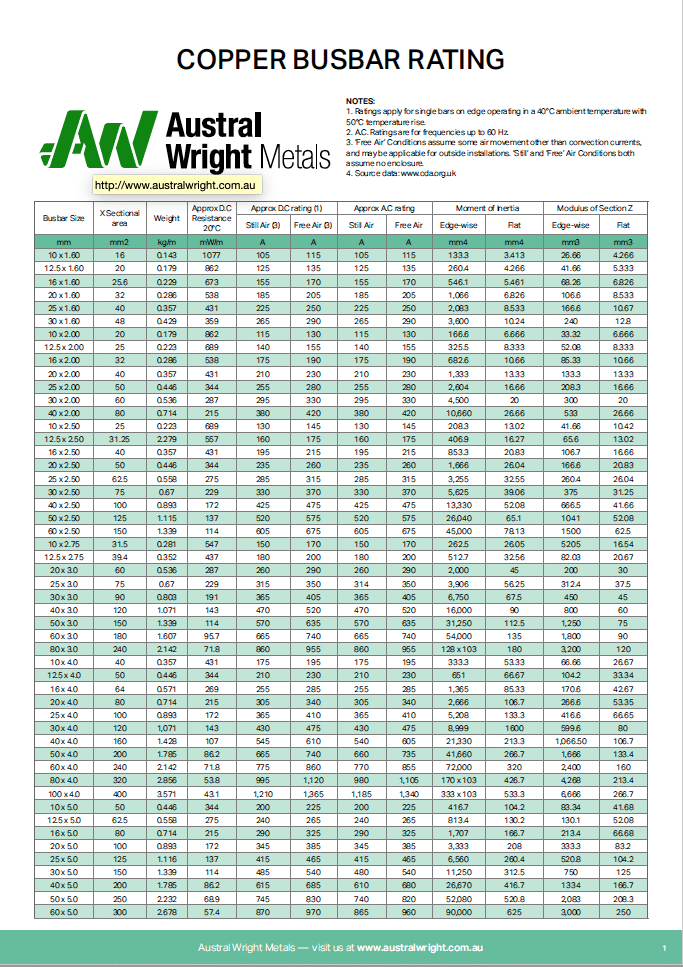

Copper Busbar Rating Austral Wright Metals

0 Response to "Copper Busbar Current Carrying Capacity"

Post a Comment